Why SoftShoe® is the PLM software of choice?

- Best in class: Based on 25 years of PLM and international trade software experience and global PLM best practices.

- Process and data management tailored to the footwear industry.

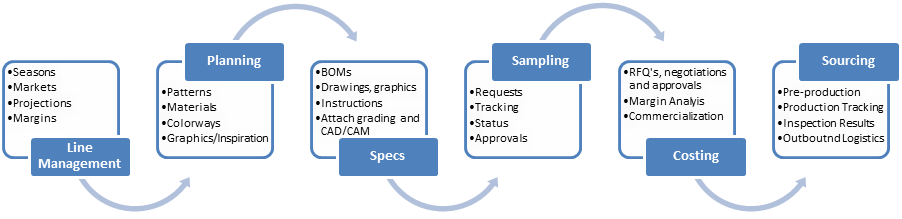

- Take your product development operations to the next level. Optimized for line and style data entry and retrieval, collaboration on specifications, sampling, costing to pricing, material management as well as sourcing.

- Integrates with other systems. Works optimally with other business process tools such as ERP and sourcing systems as well as report writers like Crystal.

- Robust and scalable technology. Easily enhanced through configuration or the licensing of addition add-ons to meet your changing needs and growing organization. Add users up to any number needed.

- Based on global best practices. The software is backed by proprietary world class footwear industry insights, gathered from many of the leading footwear companies.

- Evolves with your needs. Be assured that your evolving PLM requirements and changes in technology are proactively addressed. We have clients using SoftShoe® for close to 15 years.

- Positive customer reviews. 98% of customers would recommend others to use GTS’ software and services.

WORLD CLASS ENTERPRISE PLM SOFTWARE FOR THE FOOTWEAR INDUSTRY

Increase sales 2% – 5%, boost margins by 1%- 3%, reduced prototype iteration rate by 50 – 65%, decrease calendar lead times by 15%. *

Developed by a team of PLM, international trade specialists and software specialists, SoftShoe® is an enterprise PLM application tailored to the requirements of the footwear industry.

* Read more on consumer driven product development and PLM benefits here.

SoftShoe® Overview

SoftShoe’s comprehensive out of the box features and completely open API combined with its advanced user interface capabilities provide a powerful PLM solution for the footwear industry.

It facilitates effective communication and collaboration, synchronizes distributed product teams and streamlines products into integrated processes across their life cycle. By using a single solution as SoftShoe, your global footwear teams can work together resulting in a more effective and efficient manner, speed development, commercialization and production time and boost quality. SoftShoe sets the stage for innovation, not administration.

SoftShoe:

Enterprise PLM for the

Footwear Industry

Download Now

Modules and Features

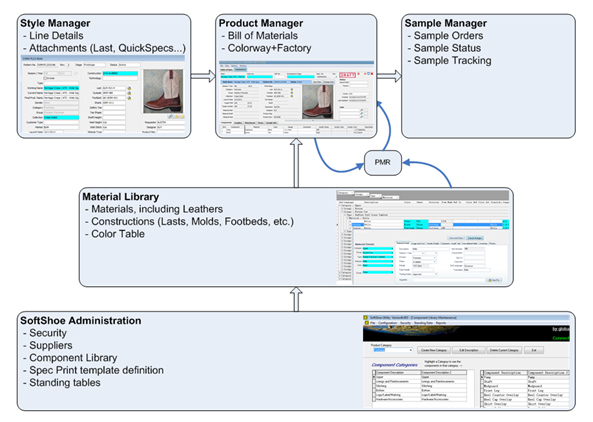

- Style Manager

- Product Manager

- Material Library

- Sample Manager

- Costing/Pricing

- Integration & BI

- Addons

Style Manager

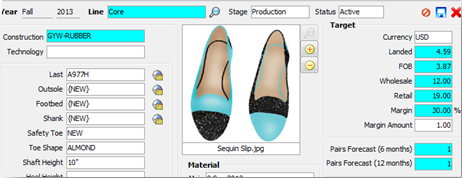

The creation and compilation of line plans and seasonal style briefs in a collaborative environment is critical to the global process for the design and development of market right footwear product for each region, market and/customer. Style Manager allows you to do just that.

- Line Management: Create them any way you wish such as collection, season, and year or by customer, season, year.

- Style Brief: Capture and manage design/style elements, i.e., main materials, projected colors ways, and construction details such as last/outsole/foot bed/shank. To ensure better reporting through consistent data, most fields link to pre-defined tables for style and construction details, product categorization, market and customer information, status and more. Target costing and pricing details as well as projected volumes can also be captured. Completing the Brief is the ability to capture design sketches, line drawings, and photos of print samples, logo details, pattern cutting and/or stitching details allowing you to illustrate and communicate design/style objectives.

Product Manager

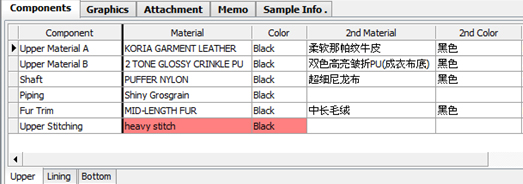

Critical to taking a style from concept to sample and then production is the Bill of Materials (BOM). Sample Rooms and/or manufacturers rely on the detailed information that is included in the BOM) to build a product. In the footwear industry, these BOMs must be at the colorway level in order to track accurate receipt, acceptance or rejection of samples and production. For every Style created with Style Manager, Product Manager can generate one or many colorway BOMs. Sample Requests can also be generated from Product Manager (see further details on Sample Manager here).

- BOM Details: Capture components and material details. Provides on-line access and selection from:

- Material Library: Integration to the SoftShoe Materials Library module allows for easy searching and selection of approved materials ensuring better control of material development, testing, usage and costs. Unapproved materials, a material color and/or vendor are redlined in the BOM.

- Component Library: Provides standardization of component and construction names and a global dictionary of terms. BOM templates can be predefined with the Component Library. Alternatively, you can perform an incremental search and add them to your BOM in Product Manager.

- Graphics/Attachments/Memo: Attach graphics drawings/images, other critical documents and make construction comments.

- Sample Requests:Ability to generate sample requests and view existing orders and history.

- Customized Views: Change the order or the width of the columns and save the view to suit your preferred workspace. Product Manager delivers all the functions to replace Excel spreadsheets including Copy & Paste, Find & Replace, Lock Columns and Set Font, for example.

- Audit Log: Product Manager includes a built-in change management tool that allows you to monitor and audit changes for each and every product specification. This function gives you unprecedented history of who changed what and when.

Material Library

The Material Library allows you to establish a hierarchy and categorize materials to fit your business. Organizing materials makes browsing, searching and accessing data easy. This Material Library provides a single global repository for materials and their associated testing as well as material reference tables for lasts, colors and molds data.

Update Materials

- Material Library: Capture attributes pertaining to each material as well as vendor details, costs inventory details and user-defined information.

- Material Reference: Capture ID and attribute data related to lasts, colors and molds.

Query Materials

- New Materials: View missing materials contained in BOM’s by year, season and/or division. These on-line reports can be exported to Excel for review and allow for data entry of these new materials into the Material Library.

- Material Usage – Where Used?: Find, select and update any BOM’s containing a specific material that may no longer wish to use and have replaced.

Testing Materials

Define at any time the material tests to be performed.

- Testing Types: Defines component categories needed to be tested. (i.e. leather, foot bed, etc.)

- Organizations/Standards: Defines the testing standards/organizations such as ASTM, SATRA or MIL

- Set up Tests: Defines each test by Type, Organization/Standard, Test ID (tensile, tear, color fastness, etc.) and acceptable quality ranges in terms of defects against sample quantities.

User can then capture the results received from the vendor against the material stored in the Material Library. Performance reports can be written to evaluate vendors with the same material types or however you wish to measure performance.

Sample Manager

Sample Manager is designed to facilitate the entire process — from initial request and order right through to the tracking, receipt and distribution.

- Manage multiple sample requests of any type (proto, confirm, sales or other).

- Generate Tech packs and supporting images and documents.

- Tracking: Capture receipt dates and status

- Ability to capture, assign, process and communicate sample requests from head office or from anywhere in the world.

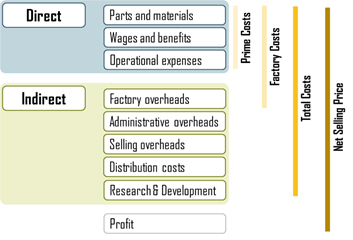

Source: STRUCTURE OF PRODUCTION COSTS IN FOOTWEAR MANUFACTURE, Prepared by Ferenc Schmél UNIDO Secretariat, http://www.unido.org/fileadmin/import/userfiles/timminsk/leatherpanel14schmelcosts

In the accounting world, there are many approaches to analyzing and booking Cost of Goods Sold, but in practice, there are two methods employed in the footwear industry.

- Ask one or more suppliers to quote a price based on quantity, delivery time frame and a Tech Pack and perhaps even a physical sample

- Calculating estimated cost before approaching a manufacturer to negotiate based on material usage, costs and historic labor and tooling costs in a Cost Breakdown sheet.

In SoftShoe, we have two alternative add-on modules to address each approach.

The Pricing module uses the concept of Price Requests and Request for Quote to several factories. Your negotiating leverage comes from the fact that you are forcing factories to compete and bid for the business.

Alternatively, the Costing module creates a Cost Breakdown Sheet that calculates expected cost, so that you can go into the factory armed with data, increasing your negotiating position. This approach also lets you decide earlier in the development process if making target margin is even possible given the design and materials.

ERP Integration

GTS has integrated its PLM solutions to a host of ERP solutions. Exporting critical data on commercialized styles is critical to any order management solution. Re-inputting data which is prone to error and is a redundant task is eliminated.

Business Intelligence

Regardless of whether you are a designer, line builder, overseas developer or a senior executive, personnel at all levels need reports that are concise, timely and tailored to their task needs.

By using a business intelligence solution, such as Crystal Reports, users get the right information for their product development needs from SoftShoe.

Sample reports include:

Seasonal Line Status

Sample Order Status/Timeliness

Pre-production Status

Cost and/or Pricing Status

Commercialized Lines

…and much more.

Historical, current and predictive views of SoftShoe information facilitate decision making and improve customer service.

PM Change Manager

This module allows users to create change requests for BOMs and for authorized users to approve the changes. Once the approval process is completed, these changes are then applied against the BOM in Product Manager.

Production Planning & Tracking

This add-on allows overseas staff to view orders and update key production milestones, both planned and actual.

Factory Access

In order to reduce time and resources within your own organization, this add-on gives suppliers accessibility to view and/or update of tasks and processes.